What is welding?

It is a process of fabrication which helps in joining materials, usually metals by causing fusion that helps in melting metals, unlike soldering which does not melt metals. Along with the base metal, a filler metal is also joined, in order to make the joint even stronger than the base metal. In general, a weld is formed by using pressure in conjunction with heat.

What are the types of welding processes?

The welding process is classified into two major categories namely fusion processes and solid phase processes.The fusion processes include the following popular methods,

- Shielded metal arc welding-That uses an electrode to create the weld.

- Gas tungsten arc welding-That uses a tungsten electrode to create the weld.

- Gas metal arc welding-That uses a wire feeding gun to help feeding the wire at and adjustable speed

- Flux cored arc welding-That uses a tubular wire filled with flux.

- Submerged arc welding-That uses a consumable electrode, which is automatically fed and a blanket of granular fusible flux.

- Electroslag welding-That uses a single pass welding process for welding materials that are thick.

The solid phase process does not involve melting the metal before joining.The popular types include the following methods,

- Ultrasonic welding-This connects the metals by vibrating them at high frequency and under high pressure.

- Explosion welding-This method involves pushing the metals together to join with the help of high extreme pressure.

- Friction welding-It uses mechanical friction to fuse materials with the help of a lateral force called upset.

- Cold welding-It uses the vacuum to help in attaching two metals together.

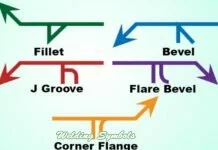

What are the major welding joint types?

The welding joint includes the five major types of joints namely, butt joint, lap joint, corner joint, edge joint, T-joint, U-joint, and V-joint. Certain welding processes requisite the use of specific welding joint design.

Quality & Defects

The quality of a welded product depends on certain factors such as the method used to weld, the concentration of energy, the weldability of the base material, filler material, and the flux material, design of the joint and mainly the interaction between the all the above factors.

The types of welding defects include cracks, distortion, gas inclusions, and non-metallic inclusions, lack of fusion, incomplete penetration, lamellar tearing, and undercutting. To help in detecting and analyzing the quality of welding defects, methods such as visual inspection, radiography, ultrasonic testing, phased-array ultrasonics, dye penetrant inspection, magnetic particle inspection or industrial computed tomography is used.

How to extend the lifetime of the metals after welding?

The lifetime of the welded materials is figured out by the weld transitions in particular. With the help of treatments such as grinding, shot peening, and the High-frequency impact treatment, the durability of the metal can be increased to a certain extent.

What are the risks involved?

Even though, welding is beneficial there are also several risks involved associated with it. In general, welding is referred to as the hot work process as it majorly uses electric arc or flame. This can cause several injuries and fire if no precautions are followed. Apart from the flames and extreme heat, it can also damage the eyes and cause inflammation. Even if the person is not involved in welding and is standing near to the area, he may be affected with the fumes produced by the oxides used in the process.

What are the precautions to be followed?

However, these risks can be avoided by following certain precautionary advises. The first of all those is wearing the personal protective equipment before starting to weld or even enter the area. This has to accompany with wearing the welding helmets with dark UV-filtering face plates to withstand brightness. The use of goggles is also recommended to protect the retinal and corneal damage due to over exposure of heat. In order to avoid the breathing of fumes, the oxygen has to be limited in certain types of welding and by keeping the combustible materials away from the workplace.

We hope that the article in this website would have helped you to get a brief about what welding actually is. In case of queries or if you need more details about a particular article in depth, feel free to contact us through the contact form given in the website. You can also write to us about the articles we have missed if any so that we will add it too. Mark our website as one of your favorites as we keep adding articles time to time. So start reading and enjoy the heat.

[…] What is Welding? […]