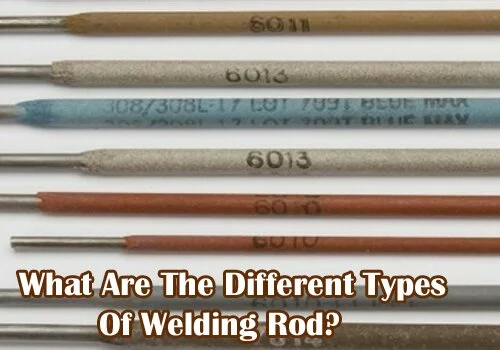

Welding rods are used to conduct current through the metals to fuse together the two parts. They are used for industrial or for commercial purposes. It is available in different sizes and shapes. Various welding rods are used for different purposes. We have listed the types of welding rods and how these rods are used to weld the different parts of metals.

Different Kinds of Welding Rods

- 6010 arc welding rods are used in the pipelines and fills in the pipes. It can be used to weld on direct current only and not on AC. It provides excellent control of arc. This rod gives deep penetration and works well in all positions.

- 6011 arc welding rods are specially designed to be used in the AC and the direct current electrode. It requires more manipulation than others. It is used in the industry and construction of steam pipe lines. It seems to be hard to run than other welding rods.

- 6013 are welding rods that are considered to be the farmers welding rod and this rod is basically designed for farmers alone. It provides a clean and smooth welding and it does not dig through the rust or paint. It is recommended for low open circuit voltage.

- 7018 welding rod helps to weld the pipes, structural steel welding and it can be used to repair all kinds of damaged parts in the pipeline system. It is considered to be the backbone of the welding. It produces smooth and strong welds. It does not release hydrogen. For this reason, this type of welding rod is used in the structural welding. It is used in the factories, dams, bridges, powerhouses and nuclear power weapons. As it contains a hydrogen free flux, the rod has to be stored in the place in which no moisture is present.

- 7024 rod is suitable for flat and horizontal welding, but it is not suitable for vertical or overhead welding. It offers a mild penetration. It can be used easily because the thick flux is used to maintain arc length and it helps in dragging the rod according to your needs.

Risks

Avoid opening the wrong end of the box and throwing away the box at the time of storage as it will break the rods. If the flux breaks only off the tip, the rod can be used. But when the flux had been broken in a part other than the tip,the welding rod become useless.

It is preferred to choose a rod with respect to the type of welding you do and according to the type of welding machine you use.