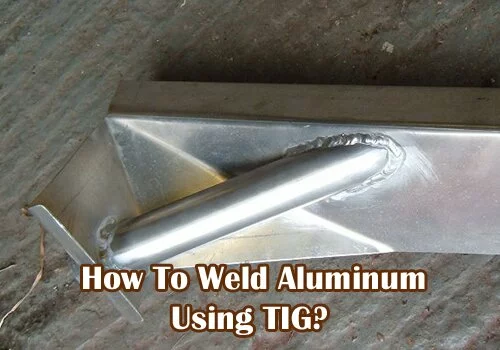

TIG is an arc welding process that provides great control and stronger welds than others. Aluminum is the most popular metal and available abundantly all over the world. It is the best metal to do the TIG welding as it contains certain unique features. This article features the welding of aluminum using TIG.

How to weld aluminum?

Many metals are TIG welded but the most common one is aluminum. You have to use the metals which possess small thickness. Most of the metals are not suitable for TIG welding as they are having very low melting points. At the time of melting, the metals are not capable of changing its color. As aluminum is having high melting points, it is considered to be the best metal for TIG welding. Even at a lower temperature, the aluminum starts to melt. Besides, the oxides are heavier than aluminum tends to sink in the molten aluminum.

Requirement

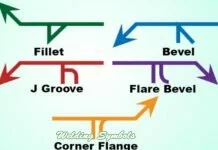

It requires a shielding gas, the non-consumable electrode made of tungsten and a surface to remove the oxides.

What are the steps involved?

- Beginners usually make a lot of scraps. Strike an arc against a piece of aluminum,the torch, and the hand needs to be positioned properly by keeping the torch in the base of your hand in a forward moving position. Between the workpiece and tungsten, there should be close distance. If you place the tungsten at a longer distance , you may lose the puddle control.

- With the help of hand and torch, do the work without striking an arc. Use the gloves while welding.

Advantages of TIG Welding Aluminum

A filler rod may not be necessary. It is considered to be the high-quality welds and hence, it won’t get damaged very easily. No splatter or no slag arises from the welding. In this TIG welding, fusion welding may be possible. The welding can be performed on various metals, but it provides superior performance on thin materials. TIG welding can be done at all the position of metals. TIG welding is suitable for magnesium, stainless steel, and copper alloys.

Disadvantages of TIG Welding Aluminum

As the shielding gas cylinders and hoses are heavyweight materials, they lack portability. It is tedious to carry these materials from one place to another place. This TIG welding is not suitable for outdoor welding as the shielding gas may produce contact with air and release harmful gasses which in turn affect the respiratory system of the human beings. The TIG welding has to be performed by the professionals having enough skill to perform well. It is a slow process and requires only a lower level of deposition rates, it is mandatory to keep the base materials very clean.

If you find it useful, Kindly share it on social networking sites.