Are you a beginner in welding, then you should know about the basics of the welding process. Generally, welding is a material joining process that makes permanent joints in the metals. Welding can be done from low level to the high level. Low-level welding includes welding small components such as vessels, few metal parts etc. The high-level welding includes underwater welding. The beginners should have the knowledge about welding, its types, process, and about its basic measures.

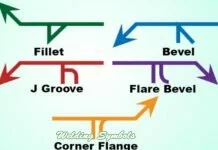

Welding types

There are about 30 different types of welding. These types are broadly classified into 4 types; they are arc welding, MIG welding, TIG welding and electrostatic welding.

Arc welding

This is one of the easiest and cheapest welding processes. This process consists of an electrode that produces an electric arc. The electric arc generates heat of about 6500 degrees Fahrenheit. This heat melts the electrode and base metal and welding occurs.

MIG welding

This is also referred as gas metal arc welding. In this welding, a solid wire is used. This wire is fed into the base metal and when the electric arc is produced, the metal melts and joins. This welding is covered with carbon dioxide gas to keep the weld safe from oxides.

TIG welding

This is referred as gas tungsten arc welding. It uses tungsten metal that does not melt at high temperature and the gas enclosed is the argon gas.

Flux welding

This welding is similar to the MIG welding with a difference of using a tubular wire in place of the solid wire.

Welding equipment

The various equipment used in welding are

Welding torch

The welding torch is used to produce electric spark during welding.

Power supply

The power supply is an important factor in welding and uses a constant power supply.

Electrode

The electrode is made out of metals or alloy that heats the base metals and joins them.

Shielding gases

These gasses are commonly used in the gas welding process. This gas keeps the weld secure and free from oxides and nitrides from the atmosphere.

Welding process

The welding process differs based on the types of welding preferred. The common process of welding will be useful to understand the basic concept of welding. The electric torch will produce an electric spark. This electric spark produces high heat and will make the base metal melt. These base metals are generally connected by the filler metal. In arc welding, the electrode itself melts and forms the filler metal. As the metal melts, it joins the base metal. This base metal is allowed to cool and check for efficiency. Generally, high efficient welding is given by MIG and TIG welding.

Welding safety

Welding safety is an important basic for the beginner. Welding safety is met by wearing welding helmets, welding gloves, and welding suit.

Welding helmets

Usually, welding process produces welding spark which is harmful to the eyes of the welder. Welding helmet and glasses are used to safeguard your eye from the powerful light.

Welding gloves

The welding gloves are used to protect the hands of the welder. The spark produced may cause damage to the welder and to avoid this problem,wearing gloves is preferred.

Welding suit

In some cases the radiations emitted will cause various health problems to the welder and hence welding suit is preferred for safety reasons.

If you are really interested in welding, the above factors will be useful for you to develop your skills. Develop your welding skills to become a professional welder.